Rotary Vacuum Film Evaporator Buchi Type Healthcare,Lab Equipment Evaporators - KFW

Rotary Vacuum Film Evaporator Buchi Type Healthcare,Lab Equipment Evaporators - KFW Specification

- Mounting Type

- Bench-top

- Accuracy

- 1C (bath temperature)

- Max Height

- Approx. 620 mm

- Display Type

- Digital / Analog

- Power Supply

- 220V AC, 50 Hz

- Interface Type

- Manual, optional vacuum controller available

- Response Time

- Instantaneous (bath heating)

- Temperature

- Up to 180C (Heating Bath)

- Operating Voltage

- 220V AC, 50 Hz

- Application

- Evaporation, distillation, solvent recovery in laboratories & healthcare settings

- Features

- PTFE vacuum seal, vertical condenser, adjustable angle

- Equipment Type

- Rotary Vacuum Film Evaporator (Buchi Type)

- Automation Grade

- Semi-Automatic

- Number of Specimens

- Single

- Specimen Size

- Flask capacity up to 1 L

- Humidity

- Ambient

- Resolution

- 0.1C (digital models)

- Port Size

- Standard 24/40

- Frequency

- 50 Hz

- Usage

- Laboratory, Healthcare, Research

- Capacity

- 1 Litre / Custom options

- Machine Weight

- Approx. 35 kg

- Test Speed

- Variable, up to 200 rpm

- Control Mode

- Digital / Manual

- Drive Type

- Motor driven, variable speed

- Vacuum Range

- Up to 20 mm Hg

- Heating Bath Material

- Stainless Steel

- Rotary Flask Material

- Borosilicate Glass

- Vacuum Seal Material

- PTFE

- Flask Capacity Range

- 250 ml to 1 L (other sizes optional)

- Condenser Type

- Double coil vertical condenser

- Cooling Surface

- 1200 cm² (approximate for standard condenser)

- Heating Bath Capacity

- 2 Litres

- Rotation Motor Power

- 40 W

- Safety Features

- Over-temperature cut-off, water level sensor (bath)

About Rotary Vacuum Film Evaporator Buchi Type Healthcare,Lab Equipment Evaporators - KFW

Rotary Vacuum Film Evaporator Buchi Type Healthcare,Lab Equipment Evaporators KFW :

This model of evaporator is supplied complete with A.C. non-sparking geared drive unit, support stand fitted with Jack arrangement of stainless steel rod for positioning glass assembly, variable speed regulator, thermostatically controlled stainless steel water bath fitted on a Jack, double coiled glass condenser with three opening for vacuum and cooling, pear shape evaporating flask capacity 800 ml. receiver flask capacity one litre with ball joint, feeding tube and vapour path tube, a complete working unit. All parts are powder coated with apoxy/polyster Hybrid, textured, Siemens, grey finish.

Precision and Versatility for Laboratory Applications

This rotary evaporator includes a variable-speed motor, digital/manual controls, and accommodates diverse flask sizes (250 ml to 1 L, with options). It is designed for safe and efficient evaporation and solvent recovery processes in pharmaceutical, research, and healthcare settings, delivering consistent performance thanks to its robust construction and intuitive control interface.

Enhanced Safety Features

Safety is prioritized with features such as an over-temperature cut-off and a water level sensor for the heating bath, ensuring worry-free operation. The PTFE vacuum seal offers durable, leak-proof performance, while the stainless steel bath provides resistance to corrosion and ensures longevity, making the equipment ideal for extended use.

Efficient Cooling and Temperature Control

The double coil vertical condenser, offering approximately 1200 cm of cooling surface, alongside the rapid-response stainless steel heating bath, guarantees efficient evaporation and temperature stability. This design minimizes solvent loss and enhances recovery, supporting a wide range of laboratory workflows with precise digital/analog monitoring.

FAQs of Rotary Vacuum Film Evaporator Buchi Type Healthcare,Lab Equipment Evaporators - KFW:

Q: How does the Rotary Vacuum Film Evaporator (Buchi Type) operate during solvent evaporation?

A: This evaporator utilizes a rotating borosilicate flask immersed in a stainless steel heating bath, while vacuum is applied to lower the boiling point of solvents. The solvent vapors pass through the vertical double-coil condenser where they are efficiently cooled and condensed for recovery or disposal.Q: What are the key benefits of using borosilicate glass for the rotary flask?

A: Borosilicate glass is highly resistant to thermal shock and chemical corrosion, ensuring safe solvent handling and long-term durability. It is ideal for various chemicals and solvent recovery processes in laboratory and healthcare settings.Q: When should I use the over-temperature cut-off and water level sensor features?

A: These built-in safety features should always be utilized during operations. The over-temperature cut-off prevents overheating, while the water level sensor protects the heating bath from running dry, ensuring safety and reliability during evaporation procedures.Q: Where can this rotary evaporator be installed and operated effectively?

A: The evaporator is suitable for benchtop installation in laboratories, research facilities, and healthcare environments. Its compact size and durable construction make it ideal for space-constrained settings without compromising functionality.Q: What is the process for changing the flask or adjusting the condenser angle?

A: After ensuring the device is powered off and pressure is equalized, the flask can be interchangeably mounted or replaced based on size requirements. The vertical condenser angle is adjustable to suit workflow or optimize condensation efficiency as desired.Q: How does the variable speed function enhance the evaporation process?

A: Variable speed rotation (up to 200 rpm) improves the distribution of the liquid film inside the flask, resulting in faster evaporation rates and increased efficiency, especially for viscous samples or large volumes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Testing & Measuring Equipment Category

Tincture Press Healthcare,Lab & Life Science Lab Equipment Tincture Press - KFW

Temperature : Room Temperature Operation

Control Mode : Handoperated, Screw Mechanism

Machine Weight : Approx. 8 kg

Capacity : 500 ml (Press Volume)

Measuring Range : Up to 2 Ton Force

Application : Healthcare, Laboratory, Pharmaceuticals

Digital Colony Counter

Temperature : 5C 40C

Control Mode : Digital

Machine Weight : Approx. 2.5 kg

Capacity : Single dish

Measuring Range : 0 9999

Application : Microbiological Colony Counting

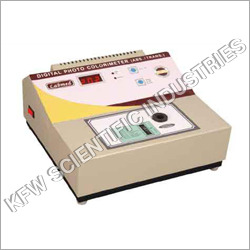

Digital Photo Colorimeter Micro Controller

Temperature : 10C to 40C

Control Mode : Micro controller based

Machine Weight : 2.5 kg approx.

Measuring Range : 0 to 100% Transmission, 0 to 2.00 OD

Volumetric Burette

Temperature : 1040C

Control Mode : Manual

Machine Weight : Approx. 250 g

Capacity : 50 ml / 100 ml

Measuring Range : 0 to 100 ml

Application : Laboratory Liquid Measurement, Titration

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry