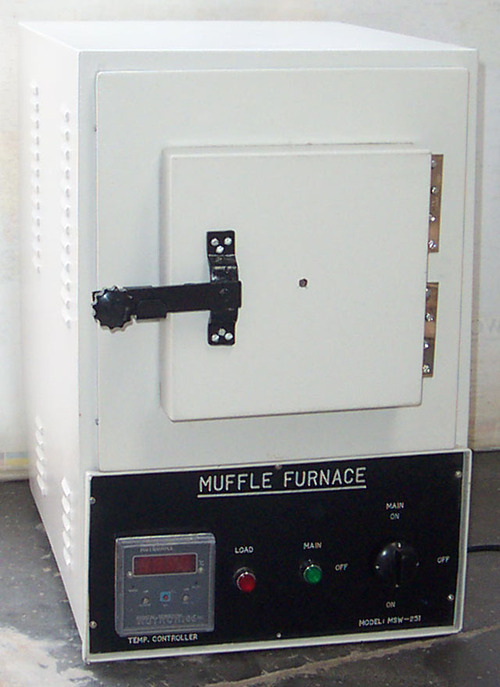

MUFFLE FURNACE

Price 11500.0 INR/ Piece

MUFFLE FURNACE Specification

- Feature

- Good Quality

- Operate Method

- Manual

- Power Source

- Electric

- Material

- MS

- Usage

- Industrial

- Voltage

- 110-215 Volt (v)

MUFFLE FURNACE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Day

- Delivery Time

- 5 Days

- Main Domestic Market

- North India, East India, Meghalaya, Manipur, Andhra Pradesh, Goa, Jharkhand, Odisha, Punjab, All India, Central India, West India, Karnataka, Assam, Delhi, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Pondicherry, Uttar Pradesh, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Uttarakhand, South India, Mizoram, Bihar, Chandigarh, Daman and Diu, Gujarat, Kerala, Lakshadweep, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, West Bengal

About MUFFLE FURNACE

MUFFLE FURNACE Lab Science FurnacesLab Equipment Furnaces Laboratory Furnaces KFW

MUFFLE FURNACE KFW Outer shell made out of thick mild steel duly finished in attractive stoving enamel paintMUFFLE FURNACEFitted withgrooved refractory for supporting the heating elements made out of wire and are easilyreplaceable Maximum temp 1000oC with working temp 940oC controlled by SUNVIC energyregulator but maximum temp 1150oC with working temp 1100oC Complete in all respects as above

Muffle Size in mm Inches

a 225x100x100 9x4x4

Exceptional Quality and Versatility

Designed for industrial environments, our muffle furnace boasts a sturdy MS body and advanced electrical heating components. It is suitable for processes like material testing, ash determination, and heat treatment. The robust build ensures long-term reliability and safety during operation.

User-Friendly Manual Operation

The furnace is manually operated, offering the user direct control for accurate temperature setting and process management. This operational style is ideal for technicians who prefer hands-on adjustment and monitoring throughout their heating applications.

Trusted Across Indian Industry

We operate as a distributor, exporter, manufacturer, supplier, and trader, ensuring nationwide availability and comprehensive support. Our muffle furnaces are trusted by industrial clients across India, who rely on us for quality products and prompt service.

FAQs of MUFFLE FURNACE:

Q: How should the MUFFLE FURNACE be manually operated?

A: To operate the muffle furnace manually, connect it to the correct power source (110-215 Volt), place the sample inside using tongs, and adjust the temperature settings to your required value. Monitor the process throughout, and switch off the furnace after completion, allowing it to cool before removing samples.Q: What industrial applications is the MUFFLE FURNACE suitable for?

A: This furnace is ideal for high-temperature processes such as material testing, incineration, ash content determination, heat treatment, and ceramic firing. Its good build quality and reliability support consistent use in laboratories and industrial plants.Q: When should the heating process begin in the MUFFLE FURNACE?

A: Begin the heating process only after ensuring that the workpiece is securely placed inside, the furnace door is closed, and all safety protocols are followed. Double-check that the power supply matches the required voltage range of 110-215 Volts before starting.Q: Where is your MUFFLE FURNACE manufactured and supplied from?

A: Our muffle furnaces are manufactured and distributed throughout India. We operate as a manufacturer, supplier, distributor, exporter, and trader, ensuring rapid delivery and support to industrial clients across the country.Q: What is the process for heating samples using the muffle furnace?

A: First, set the desired temperature manually. Place the sample inside the chamber using appropriate safety equipment. Power on the furnace and monitor temperature levels throughout the cycle. After the process, switch off and let the furnace cool before safely retrieving the sample.Q: How does using an MS material benefit the furnace?

A: MS (mild steel) provides durability, stability, and resistance to deformation at high temperatures, making the furnace robust for industrial environments and ensuring a long service life.Q: What advantages does the electric power source offer?

A: An electric power source allows for precise temperature control, clean operation without combustion by-products, and suitability for usage where steady and reliable heating is critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratories Instruments Equipment Category

Muffle Furnace

Measurement Range : 0C to 1200C

Voltage : 220 V AC

Core Components : Heating Elements, Digital Controller, Insulation

Display Type : Digital Display

Dimension (L*W*H) : 305 x 125 x 125 mm (Inner Chamber)

Feature : High Precision Heating, Energy Efficient, Overheat Protection

Dispensing Sampling Booth

Measurement Range : Airborne Particle Filtration up to 0.3 micron

Voltage : 230 V AC

Core Components : HEPA Filter, Pre Filter, Motor Blower, Control Panel

Display Type : Digital Control Panel

Dimension (L*W*H) : 1200 x 900 x 2100 mm

Feature : Downflow air system, GMP Model, Low Noise Operation, Advanced HEPA Filtration

Slide Warming Table

Measurement Range : 070C

Voltage : 230V AC

Core Components : Temp controller, heating element, body

Display Type : Analog thermometer display

Dimension (L*W*H) : 450 mm x 300 mm x 80 mm

Feature : Uniform heating, corrosion resistant

Bio-Chemistry Analyzer

Measurement Range : 0.01 999 U/L

Voltage : 220240 V

Core Components : Optical System, Photometer, Sample Probe

Display Type : 7inch TFT LCD Touchscreen

Dimension (L*W*H) : 860 x 600 x 420 mm

Feature : Userfriendly software, High throughput, Bar code reader compatible

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry