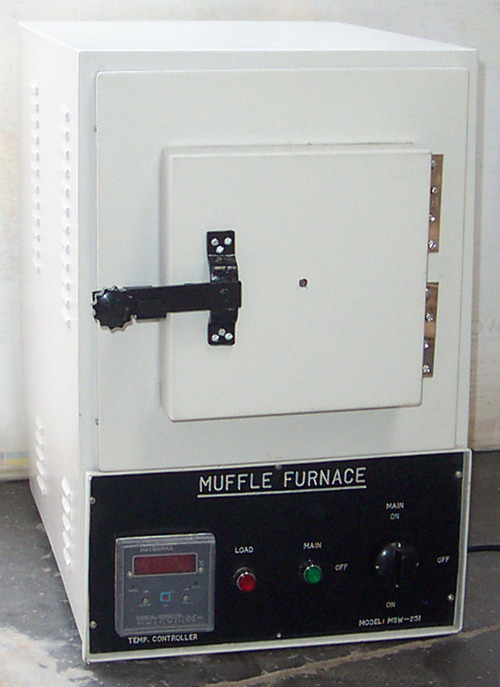

Rectangular Muffle Furnace Lab Science Lab Equipment

Rectangular Muffle Furnace Lab Science Lab Equipment Specification

- Automation Grade

- Semi-Automatic

- Response Time

- Rapid heating, reaches max temp in 3045 minutes

- Hardness

- Muffle made from high-quality refractory ceramic

- Max Height

- Depend on furnace size, typically 400600 mm

- Temperature

- Ambient to max. 900C/1100C/1200C/1400C (as per model)

- Interface Type

- Manual controls, no data interface

- Display Type

- Digital LED display

- Accuracy

- 3C at 1000C

- Measuring Range

- Room temp up to maximum rated temp

- Port Size

- Standard exhaust port size ~25 mm OD

- Power Supply

- 230V 10%, 50Hz, Single Phase AC

- Gas Pressure

- Ambient (not applicable)

- Application

- Ashing, Annealing, Sintering, Heat Treatment, Material Testing

- Equipment Type

- Laboratory Muffle Furnace

- Resolution

- 1C

- Frequency

- 50 Hz

- Mounting Type

- Bench-top

- Operating Voltage

- 230V AC, 50Hz

- Features

- High-quality ceramic fiber insulation, long life heating elements, over-temperature protection, energy efficient

- Humidity

- Ambient (not applicable)

- Specimen Size

- Depends on chamber dimensions

- Usage

- Laboratory, research, industrial testing

- Capacity

- 1.5 to 20 Litres (as per selected model)

- Machine Weight

- Approx. 40-60 kg (varies with size/capacity)

- Test Width

- Chamber width: 100300 mm (varies with model)

- Control Mode

- Microprocessor Based Digital PID Controller

- Insulation Thickness

- 65 mm (approx.)

- Temperature Uniformity

- ±5°C

- Chamber Material

- High-grade silica/mullite refractory

- Door Type

- Front-opening with ceramic lining

- Heating Element

- Kanthal A1 wire

- Chamber Dimensions

- Standard options: 225 x 100 x 100 mm; customizable

- Safety Features

- Over-temperature cut-off, fuse protection

- Outer Body

- Powder-coated mild steel

About Rectangular Muffle Furnace Lab Science Lab Equipment

We are an unparalleled name counted amongst the prominent manufacturers, exporters and suppliers of a wide array of Rectangular Muffle Furnace Lab Science Lab Equipment. Offered furnace is manufactured at our well equipped manufacturing unit using high quality components and latest technique to ensure its superior performance. Due to its fast heating mechanism, this furnace is useful in various industries including paper, plastic, automobile, etc. Moreover, we provide this Rectangular Muffle Furnace Lab Science Lab Equipment in diverse technical specifications in order to fulfill clients specific requirements.

Features:

-

Shock proof body

-

Negligible maintenance

-

Robust design

-

Power efficient

Muffle Size in mm & Inches

a) 225x100x100 (9x4x4)

Unmatched Thermal Uniformity and Efficiency

Engineered for optimal temperature stability, the Rectangular Muffle Furnace features advanced insulation and precision controls, maintaining uniformity within 5C. Its rapid heating, reaching maximum temperatures within 3045 minutes, ensures efficient workflow in labs, research facilities, and industrial testing environments. The ceramic fiber insulation and robust heating elements contribute to long operational life and energy efficiency.

Versatile Design with Customizable Chambers

Standard chamber dimensions (225 x 100 x 100 mm) can be tailored to individual laboratory needs, accommodating specimens of various sizes. The front-opening door with ceramic lining provides user convenience and safety during loading and unloading. The furnace is suitable for benchtop installation, adapting seamlessly to limited or flexible lab spaces.

Comprehensive Safety and User Control

Safety remains paramount with integrated over-temperature cutoff and fuse protection. The digital LED display and microprocessor-based PID controller allow users to monitor and precisely regulate furnace conditions. With manual controls for straightforward operation, the furnace prioritizes safe, accurate, and consistent thermal processing.

FAQs of Rectangular Muffle Furnace Lab Science Lab Equipment:

Q: How do I operate the Rectangular Muffle Furnace safely and effectively?

A: To safely operate the furnace, ensure it is properly connected to a 230V AC, 50Hz single-phase power supply. Load your specimen into the chamber, securely close the front-opening door, and set the desired temperature on the microprocessor-based digital PID controller. Safety features such as over-temperature cut-off and fuse protection will automatically engage if necessary. Always allow the furnace to cool before handling or maintenance.Q: What applications are best suited for this laboratory muffle furnace?

A: This furnace is ideal for ashing, annealing, sintering, heat treatment, and various material testing processes in laboratory, research, or industrial settings. Its broad temperature range (up to 1400C, depending on the model) and precise control make it a versatile tool for accurate and repeatable thermal treatments.Q: When should the heating elements or insulation be checked or replaced?

A: The high-quality Kanthal A1 heating elements and ceramic fiber insulation are designed for longevity, but regular inspection is recommended, especially after extended use at higher temperatures. Replace elements if you notice slower heating, irregular temperature maintenance, or any physical damage. Routine checks can prolong equipment life and ensure consistent results.Q: Where can I install this bench-top muffle furnace in my laboratory?

A: The furnace is designed for benchtop installation and should be placed on a stable, heat-resistant surface with sufficient ventilation. Keep it clear of combustible materials and ensure the exhaust port (25 mm OD standard) is not obstructed, allowing safe dissipation of heat and gases.Q: What benefits does the microprocessor-based digital PID controller provide?

A: The digital PID controller ensures precise temperature regulation and stability. It minimizes temperature fluctuations, maintains uniform heating (within 5C), and allows easy, accurate setting and monitoring for reliable, high-quality testing outcomes.Q: How does the chamber design and material improve furnace performance?

A: The chamber is constructed from high-grade silica/mullite refractory, providing excellent resistance to high temperatures and thermal shock. This design, combined with robust insulation, ensures minimal heat loss, superior temperature uniformity, and long service life of the furnace.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Testing & Measuring Equipment Category

Digital Colony Counter

Mounting Type : Table top

Usage : Colony counting in laboratories

Response Time : Instantaneous

Capacity : Single dish

Accuracy : 1 count

Capsule Filling Machine Health care,Lab&Life scien

Mounting Type : Tabletop/Benchmounted

Usage : Manual encapsulation of powder/granule into capsules

Response Time : Immediate manual operation

Capacity : 15001800 capsules/hour

Features : Stainless steel body, corrosionresistant, easy to operate and clean

Accuracy : High Filling Accuracy for Powder/Granules

Magnetic Stirrer With Hot plate Laboratory Magneti

Mounting Type : Table Top

Usage : Mixing and heating laboratory samples

Response Time : Instantaneous heating

Capacity : up to 2 Liter

Features : Magnetic stirring; Uniform heating; Speed control; Chemicalresistant body

Accuracy : 2C (temperature)

Volumetric Flasks KFW

Mounting Type : Benchtop/Laboratory use

Usage : Analytical and chemical laboratory processes

Response Time : Immediate upon usage

Capacity : Available in 25 ml, 50 ml, 100 ml, 250 ml, 500 ml, 1000 ml, 2000 ml, 5000 ml

Features : Calibrated, Stoppered, Transparent glass, Chemical resistant

Accuracy : 0.1 ml or as per class A/B tolerance

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry