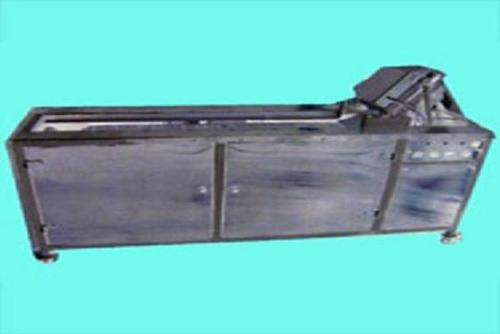

Dough Ball Making Machines

Dough Ball Making Machines Specification

- Temperature Range

- Ambient to 60C

- Frequency

- 50 Hz

- Feature

- Low maintenance, Corrosion resistant body, High efficiency

- Automation Grade

- Fully Automatic

- Voltage

- 220-240 V AC

- Model No

- DBM-900

- Measurement Range

- 20-50 grams per ball

- Capacity

- 800-1000 dough balls/hour

- Core Components

- Motor, Rollers, Conveyor, Electric panel

- Accuracy

- 1 gram per dough ball

- Power Source

- Electric

- Equipment Materials

- Stainless Steel

- Type

- Automatic

- Usage

- Industrial, Commercial kitchens, Hotels

- Display Type

- Digital

- Dimension (L*W*H)

- 900 mm x 550 mm x 950 mm

- Weight

- 120 kg

About Dough Ball Making Machines

Dough Ball Making Machines

Specification:

KFW scientific industries is provided " Dough Ball Making Machine " at very affordable and nominal market rates . we have supplied or export our products to the customers on time as per according their specification and requirements . " Dough Ball Making Machine " are very useful to us , so this machine is mostly used in the hotel , restaurants and canteen . such type of " Dough Ball Making Machine " is made using a high quality of materials .

IMPORTANT FEATURES

There are some important features of " Dough Ball Making Machine "

1. More Effective

2. Durable

3. High Performance

4. Efficient Performance

Exceptional Efficiency and Precision

With an impressive production efficiency rate exceeding 95% and a dough ball accuracy of 1 gram, this machine ensures consistent output and minimal product waste. Automated controls and a digital display allow users to monitor and adjust settings conveniently. The robust motor and precision-engineered rollers support continuous high-volume operation, making it ideal for commercial establishments seeking to optimize production processes.

Superior Hygiene and Easy Maintenance

Constructed from stainless steel and designed with easy detachable parts, this model makes cleaning swift and straightforward. By minimizing crevices where dough can accumulate and facilitating tool-free disassembly, the machine meets hygiene standards required by commercial kitchens and food manufacturers. Its corrosion-resistant body also enhances longevity and reduces maintenance frequency.

Comprehensive Safety and Installation Support

Safety lies at the core of this model, which comes equipped with emergency stop features and overload protection. Installation services are available to ensure proper setup and operation, reducing downtime and technical difficulties. Users benefit from peace of mind knowing robust safeguards are in place, supporting safe and efficient continuous use.

FAQs of Dough Ball Making Machines:

Q: How does the 2024 Industrial Dough Ball Making Machine adjust to different dough ball sizes?

A: The machine features an adjustable measurement range of 2050 grams per dough ball, allowing users to easily set the desired size via the microcontroller-based control system. This makes the machine highly versatile for various recipes and demands.Q: What is the installation process for the Dough Ball Making Machine, and is support provided?

A: Installation is handled by qualified technicians who set up the machine, ensuring all core components like the motor, rollers, and electric panel are correctly configured. Full installation service is available to all customers, minimizing setup challenges.Q: Where is the ideal placement of this dough ball making machine in a commercial kitchen or hotel?

A: Given its dimensions (900 mm x 550 mm x 950 mm), the machine should be placed on a flat, stable surface with access to a 220-240 V AC power source. It should also be located where routine cleaning and maintenance can be easily performed.Q: What safety features does the DBM-900 include?

A: The DBM-900 is equipped with key safety mechanisms, such as an emergency stop button and overload protection, to ensure operator safety during use. These features help prevent accidents and protect the machine from excessive strain.Q: How often and by what method should the machine be cleaned?

A: It is recommended to clean the machine daily, especially after intensive use. Thanks to its easy detachable parts, components can be quickly removed, washed, and reassembled, maintaining hygiene standards and ensuring smooth operation.Q: What are the benefits of using a fully automatic, stainless steel dough ball making machine in industrial settings?

A: Using this fully automatic model enhances productivity, reduces labor costs, and increases consistency in dough ball production. Stainless steel construction ensures durability, corrosion resistance, and compliance with hygiene regulations, making the machine a reliable investment for food businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Kitchen equipments Category

Hot Air Oven

Dimension (L*W*H) : 45 x 45 x 60 cm

Usage : Sterilization, Laboratory application, Drying

Weight : Approx. 40 kg

Equipment Materials : Inner Chamber: Stainless Steel, Outer Chamber: Powder Coated MS

Power Source : Electric

Capacity : 60 Litres

Steam Generator For Rifle Electric Cleaner

Dimension (L*W*H) : 540 x 340 x 350 mm

Usage : Industrial Steam Cleaning, Rifle Maintenance

Weight : 19 kg

Equipment Materials : Stainless Steel Body

Power Source : Electric

Capacity : 6 Liters

Semi-Automatic Chapati Making Machine

Dimension (L*W*H) : 2500 mm x 700 mm x 1200 mm

Usage : Commercial Kitchen, Industrial, Canteens

Weight : Approx. 250 kg

Equipment Materials : FoodGrade Stainless Steel

Power Source : Electric

Capacity : 800900 chapatis per hour

Vegetable Cutting Machine

Dimension (L*W*H) : 900 x 460 x 800 mm

Usage : Commercial Kitchen, Food Processing

Weight : 60 kg

Equipment Materials : Stainless Steel

Power Source : Electric

Capacity : 100150 kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry