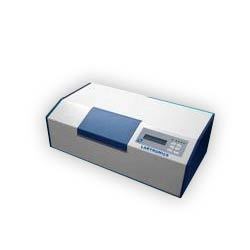

Microprocessor Flame Photometer

Microprocessor Flame Photometer Specification

- Frequency

- 50/60 Hz

- Model No

- Microprocessor Flame Photometer 1381

- Core Components

- Photodetector, Nebuliser, Burner, Microprocessor

- Temperature Range

- Optimum operating at ambient to 40°C

- Capacity

- Upto 4 elements (Na, K, Ca, Li) can be measured sequentially or singly

- Accuracy

- ± 2% for Na, K, Ca, Li

- Power Source

- Electric (AC mains)

- Automation Grade

- Semi-Automatic

- Feature

- Dual channel measurement, Curve storage, Auto cutoff, Data storage

- Voltage

- 230V AC ±10%

- Measurement Range

- Na: 0â100 ppm, K: 0â100 ppm, Ca: 0â100 ppm, Li: 0â100 ppm

- Equipment Materials

- Corrosion resistant powder coated mild steel

- Type

- Digital Flame Photometer

- Usage

- Clinical & Agricultural Laboratory Analysis

- Display Type

- Microprocessor based 16 x 2 line alphanumeric LCD display

- Dimension (L*W*H)

- 405 x 330 x 230 mm

- Weight

- Approx. 8 kg

- Burner Type

- Non-corrosive stainless steel mixing chamber

- Sensitivity

- Na: 0.5 ppm, K: 0.5 ppm, Ca: 1.0 ppm, Li: 0.5 ppm

- Calibration

- Microprocessor controlled multi-point automatic calibration

- Flame Type

- LPG/air

- Aspiration Rate

- 3–6 ml/min

- Data Storage

- Memory for up to 100 samples

- Operating Humidity

- Up to 80% RH

- Safety Features

- Automatic gas cut-off on flame failure

- Detection System

- Silicon photodiode detector

- Printer Interface

- Parallel port provided

- Sample Introduction

- Fine capillary aspiration

About Microprocessor Flame Photometer

Microprocessor Flame Photometer offered provides working in General, Serum and Urine modes with general mode sensitivity of Na:0.5 ppm, K:0.5 ppm, Li:0.5 ppm, Ca:15 ppm. Also coming with Na & K filters with Ca & Li filters made available at optional at extra costs, these have resolution of 0.1 ppm/meq with reproducibility of + 2% FS, &± 2 Digits, curve fit accuracy of + 2% FS and 20 x 4 Alphanumeric backlit LCD display support. The system also provides up to 5-Point calibration with curve fitting software and features RS-232C interface support.

Features:

- Calibration curve fit routines first order and second order

- Data displayed in concentration units i.e. ppm & meq

- Automatic filter selection

- Auto calibration feature

- Printer attachment

- PC connecting compatibility

- Sample data storage more than 500 results

- Alphanumerical key board for easy data entry

- Graphical LCD display thus easy to read

- Curve calibration using upto 5 standard

- Multiple calibration curve saving facility

- Stainless steel burner

- Auto Gas Cut off in case of power failure

- Ca & Li Filters Extra on Request Only

Advanced Measurement and Detection Technology

The Microprocessor Flame Photometer 1381 utilizes a silicon photodiode detector and fine capillary aspiration for highly sensitive detection of sodium, potassium, calcium, and lithium. Sequential and single-element measurement ensures laboratory efficiency, with accuracies as fine as 0.5 ppm for Na, K, and Li, and 1.0 ppm for Ca, making it ideal for demanding analytical environments.

Intuitive Operation with Enhanced Calibration

Multi-point automatic calibration, controlled by an advanced microprocessor, simplifies setup and guarantees consistent results. The alphanumeric LCD display provides real-time feedback, and memory capacity for up to 100 samples streamlines repeated analyses. A parallel printer interface supports quick documentation directly from the instrument.

Safety and Durability Designed for Labs

Built with a non-corrosive stainless steel mixing chamber and corrosion-resistant powder coated mild steel, the flame photometer offers robust protection against laboratory hazards. Automatic gas cut-off on flame failure adds an essential layer of safety, while the system operates efficiently on standard AC mains at 230V.

FAQs of Microprocessor Flame Photometer:

Q: How does the microprocessor-controlled calibration benefit laboratory analyses?

A: The automatic multi-point calibration feature, managed by the instruments microprocessor, ensures high analytical precision and reproducibility by configuring and adjusting calibration curves with minimal user intervention.Q: What process is followed for introducing samples into the flame photometer?

A: Samples are introduced using a fine capillary aspiration system, maintaining a consistent aspiration rate of 36 ml/min for accurate and reliable readings. This method is suitable for both clinical and agricultural laboratory samples.Q: Where can the Microprocessor Flame Photometer 1381 be used effectively?

A: This instrument is designed for use in clinical and agricultural laboratories, providing reliable measurement of Na, K, Ca, and Li in diverse analytical environments across industries including healthcare, education, and agriculture.Q: What safety features are integrated into this flame photometer?

A: Key safety features include an automatic gas cut-off system that activates if flame failure is detected, greatly reducing risks associated with gas operation during measurement.Q: When is data storage particularly beneficial during analytical procedures?

A: The built-in memory for up to 100 samples facilitates efficient workflow management, helps track sequential analyses, and supports comparative studies without the need for manual documentation after every test.Q: How is dual channel measurement advantageous in laboratory applications?

A: Dual channel measurement allows simultaneous or sequential analysis of two elements, increasing throughput and reducing analysis times, which is especially useful during routine sample screening and multi-element studies.Q: What materials and construction features contribute to the instruments durability?

A: The mixing chamber is fabricated from non-corrosive stainless steel, while the entire equipment is powder coated for corrosion resistance. These features ensure a long operational life and reliability in demanding laboratory settings.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scientific Instruments Category

Microprocessor Viscometer

Accuracy : ±1% FS

Feature : Automated measurement, easy calibration

Usage : Viscosity measurement for laboratory and industrial applications

Power Source : Electric

Automation Grade : Automatic

Measurement Range : 2 mPa.s ~ 2,000,000 mPa.s

Digital Polarimeter

Accuracy : ±0.01°

Feature : Automatic Zero Setting, Digital Readout, UserFriendly Interface

Usage : Measurement of Optical Rotation / Laboratory Analysis

Power Source : AC Electric

Automation Grade : SemiAutomatic

Measurement Range : 180° to +180°

Microprocessor Conductivity TDS Meter

Accuracy : ±1% of F.S. ±1 Digit

Feature : Automatic Cell Constant Correction, Auto Range Selection, TDS Measurement, Temperature Compensation

Usage : Laboratory/Industrial Conductivity & TDS Measurement

Power Source : 230V ±10% AC, 50 Hz

Automation Grade : Automatic

Measurement Range : Conductivity: 0 to 199.9 mS/cm; TDS: 0 to 199.9 g/l

Soil Testing Kit

Accuracy : ±2% for most parameters

Feature : Easy Operation, OnField Use

Usage : Analyze soil nutrient levels, pH, moisture

Power Source : Battery Operated and Manual

Automation Grade : Manual

Measurement Range : pH (310), NPK (Low/Medium/High)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry